Menu

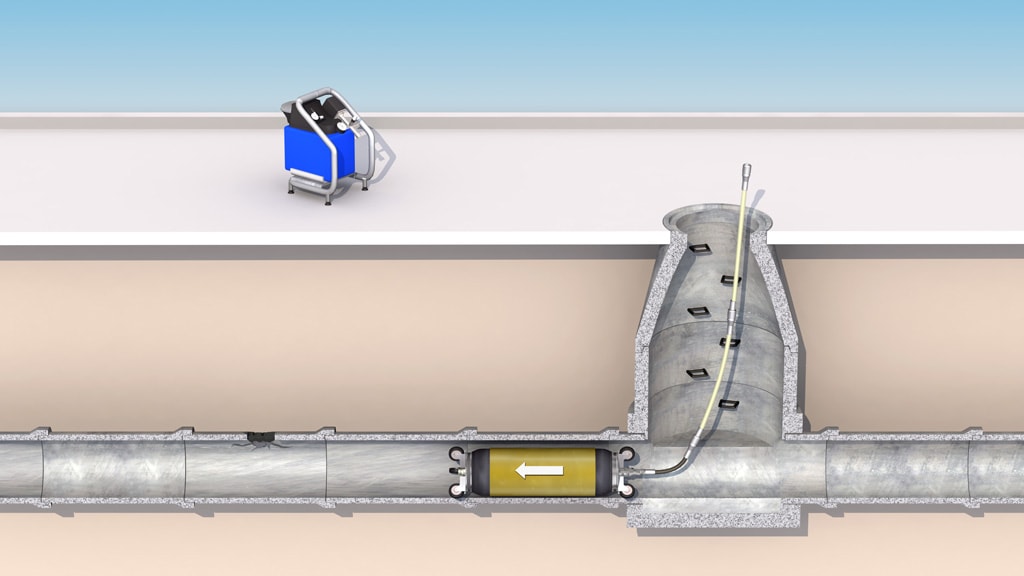

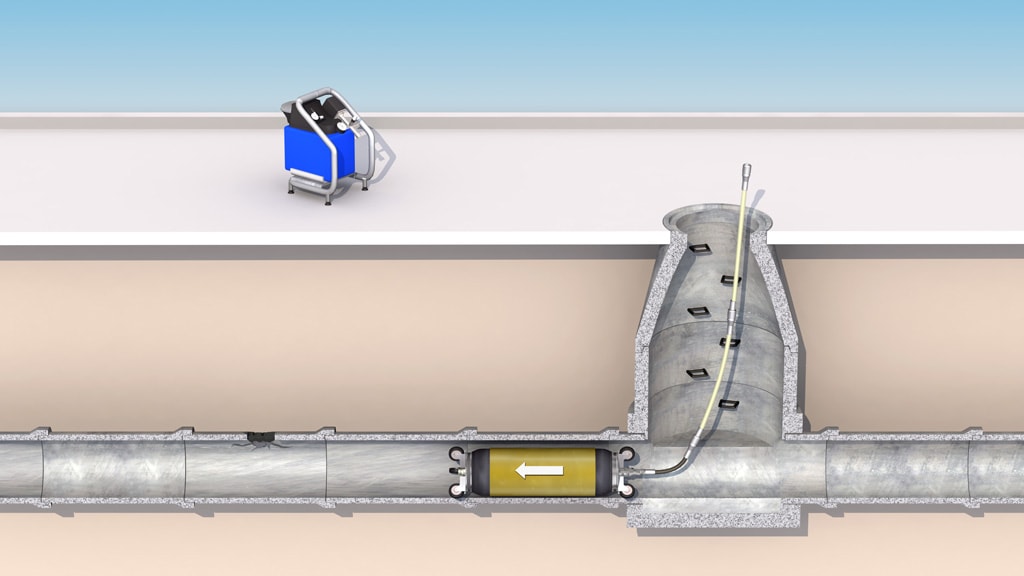

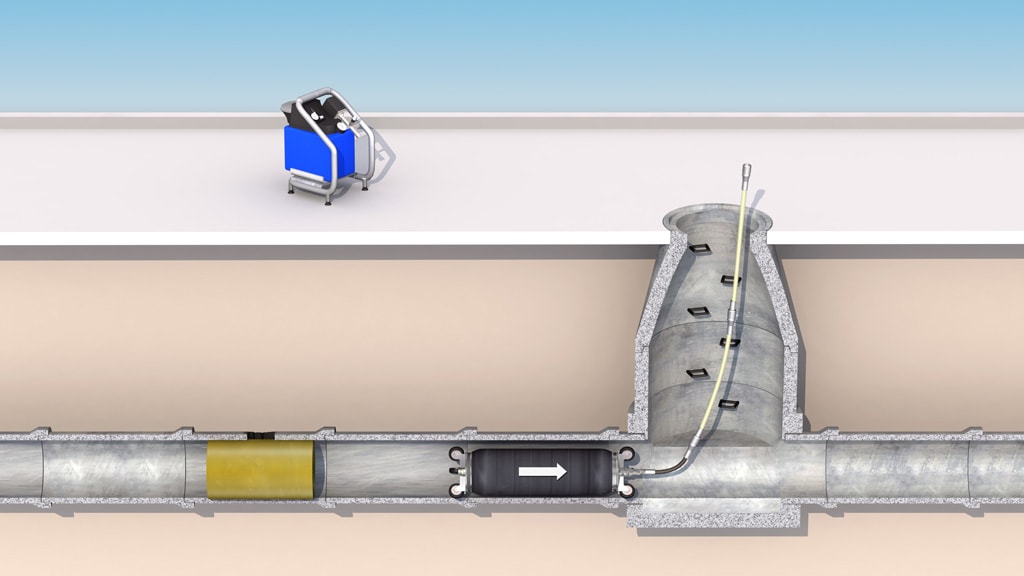

A renovation packer carrying a resin-wetted 3-layered glass fiber may construction wrapped-around is pushed with the help of air push rods or pulled by means of a rope to the point of repair.

The exact position of the point in need of repair is determined by CCTV inspection.

A renovation packer carrying a resin-wetted 3-layered glass fiber may construction wrapped-around is pushed with the help of air push rods or pulled by means of a rope to the point of repair.

The exact position of the point in need of repair is determined by CCTV inspection.

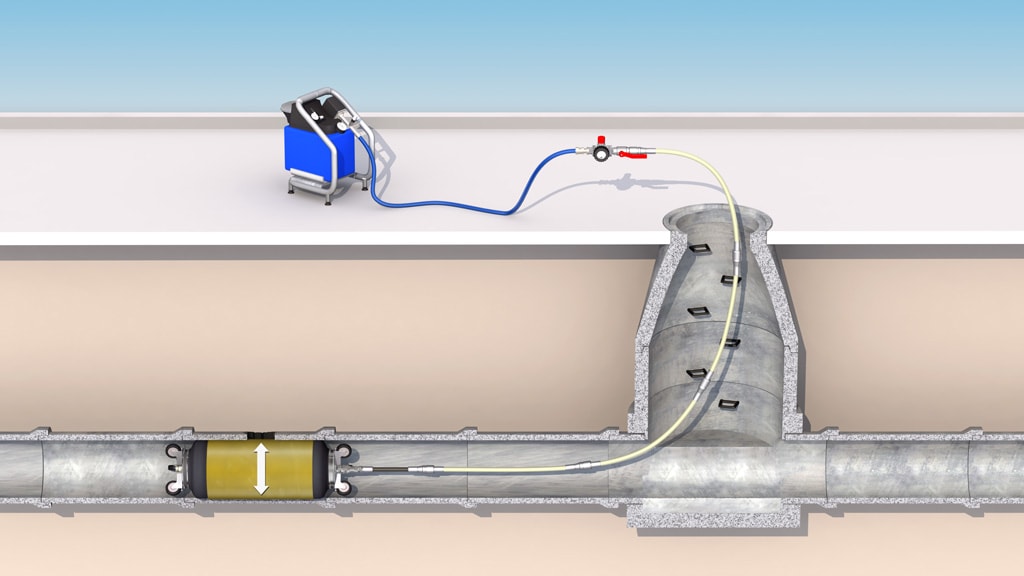

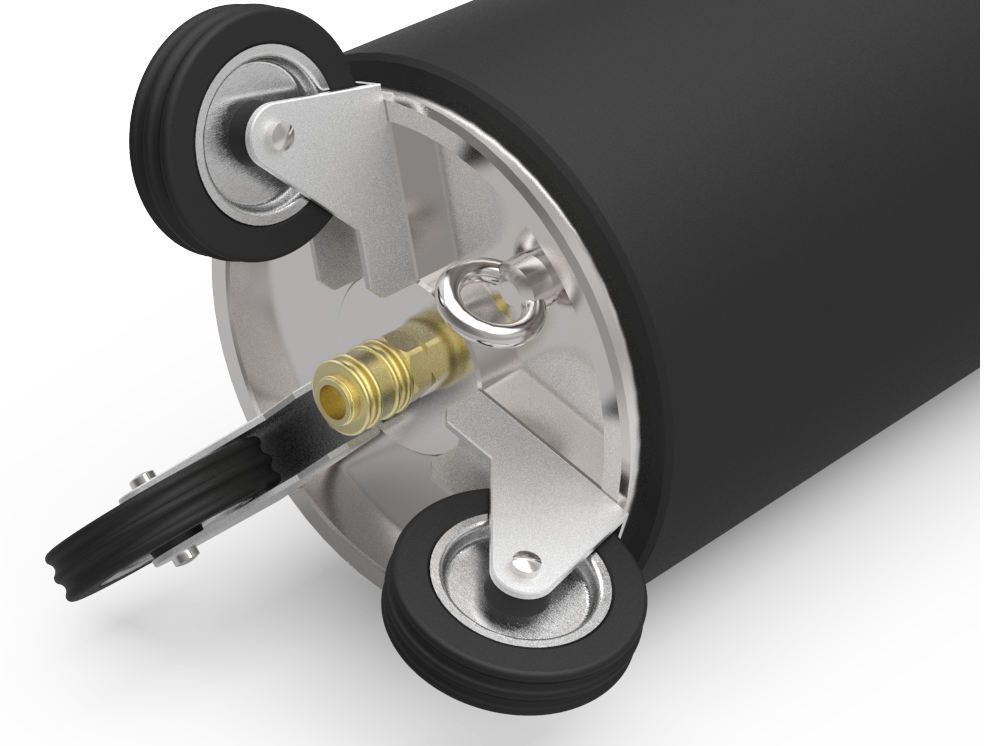

When the Packer has reached the correct position. It is gradually inflated by means of compressed air.

This causes the packer to expand towards the pipe wall and press the impregnated glass fiber mat in a tight fit against the host pipe with excessive reaction resin penetrating into the damage.

This creates a permanent bond between the glass fiber mat and the host pipe wall.

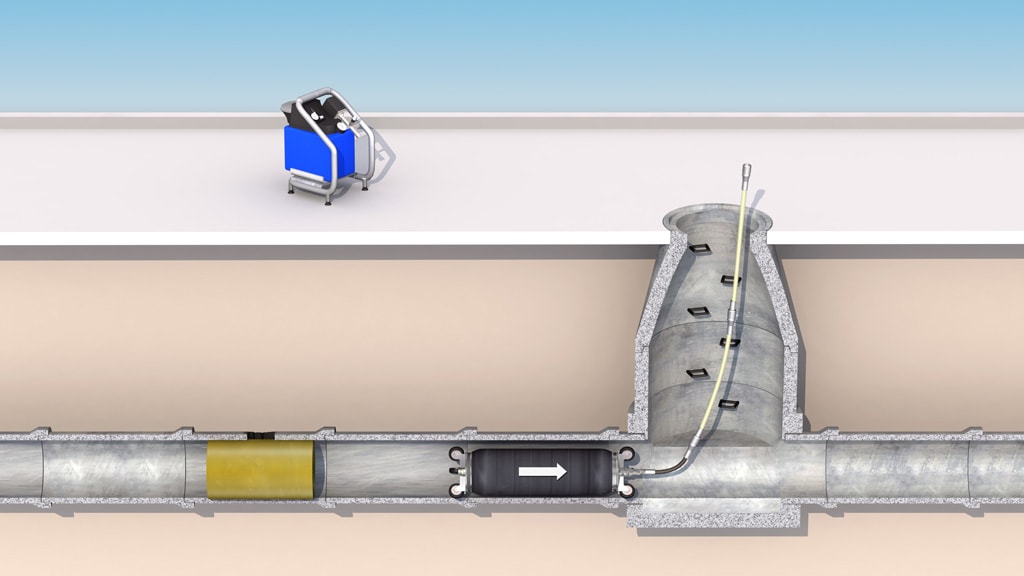

The resin-impregnated glass fiber mat will be cured at ambient temperature according to the resin manufacturer’s instructions. The required cure times depend on the climatic conditions in the sewer. After complete cure of the reaction resin, the packer is deflated and removed from the pipe.

The cured glass fiber mat covers the full area of the repaired pipe section without obstructing the service flow. The Pipe-in-pipe system thus created forms an integral system with the host pipe and fully meets the hydraulic requirements.

The resin-impregnated glass fiber mat will be cured at ambient temperature according to the resin manufacturer’s instructions. The required cure times depend on the climatic conditions in the sewer. After complete cure of the reaction resin, the packer is deflated and removed from the pipe.

The cured glass fiber mat covers the full area of the repaired pipe section without obstructing the service flow. The Pipe-in-pipe system thus created forms an integral system with the host pipe and fully meets the hydraulic requirements.

PROCORP Trading &

Contracting Co.

P. O. Box: 45527, Doha.

+974 4037 0506

info@procorp.com.qa